Metrology

Measuring Principles

Quality air bearings or precision diamond point turned surfaces can only be produced where there exists a means to accurately inspect and measure the critical features. In all cases, the standard to which measurement takes place is generally much higher than typically found in conventional quality inspection. To that end, it is often necessary to employ stringent standards and methods.

Quality air bearings or precision diamond point turned surfaces can only be produced where there exists a means to accurately inspect and measure the critical features. In all cases, the standard to which measurement takes place is generally much higher than typically found in conventional quality inspection. To that end, it is often necessary to employ stringent standards and methods.

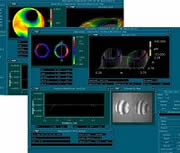

Temperature controlled environments, the use of vibration isolated measuring platforms, and air filtrations are part of these techniques and are utilized in our facility. In order to achieve reliable and accurate measurements for flatness, parallelism and squareness in the microinch range, interferometry is often utilized. Our temperature controlled measurements area contains two GPI HR interferometers and a Zygo NewView 5000 white-light non-contact optical profilometer. For sub-nanometer form and finish measurement combined, we use our state-of-the-art Talyor-Hobson Talysurf PGI 1240. These instruments allow for detailed analyses and quality control of the machined and/or lapped surfaces for both our air bearings and diamond turned metal optic parts.

Performance Measurement Certification

The aspects of a bearing which are of particular interest to designers are load carrying capacity, stiffness, air consumption and speed and damping capabilities. Our in house performance testing equipment provides this information and employs computer data acquisition for high-speed, accurate measurement. A performance certificate accompanies each bearing manufactured at Specialty Components. This certificate validates the operating characteristics required by our customers and provides a high degree of quality control of the bearing before shipment. Currently, our test fixtures can impart loads for simulation ranging from a few pounds to 10,000 pounds. In addition to load bearing aspects, our linear slides are tested for positioning accuracy using test equipment capable of measurements of distance to millionths of an inch and of angularity to fractions of an arc-second. To achieve such high levels of measurement accuracy, environmental controls aid in minimizing thermal and humidity effects. Utilization of Class 10000 level clean areas assist in assembly and packaging of components that require special handling.

Have Questions? Click here to contact us